Carbon fibre Testing

Non-Destructive Testing of Carbon Fibre Bicycle Frames and Components

Alchemy Cycle Trader has recently introduced Active Thermography Technology to test carbon fibre bicycle frames and components for accidental damage or manufacturing defects which may not always be apparent with visual inspection.

Hidden Dangers: The Risks of Undiagnosed Damage in Carbon Fibre Bike Frames

Unlike steel or aluminium bike frames where a dent or other damage is usually obvious, carbon fibre frames can delaminate or develop stress cracks as a result of an accident, overtightening of components, clamping the frame too tightly in a bike stand or rack, or even when accidentally dropped. This damage can remain hidden under paintwork and further deteriorate over time. An undiagnosed frame compromised in this manner can fail suddenly and catastrophically and poses great potential danger or even death to the rider.

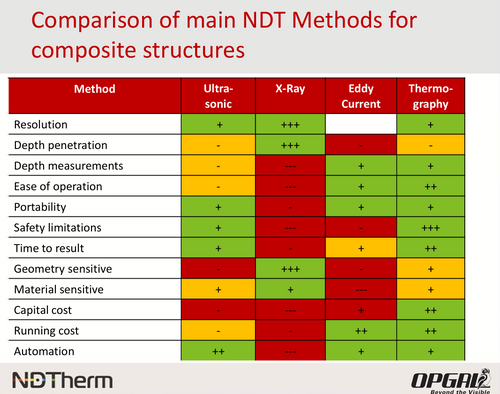

Why Active Thermography Outperforms Other Non-Destructive Testing Methods for Bike Frames

Active thermography has many advantages compared to other forms of non-destructive testing such as ultrasound, X Rays and tap

testing. While tap testing may indicate a problem with a frame, it is not always conclusive particularly around thicker parts of the frame such as the bottom bracket or headtube.

Ultrasound can only test small sections of the frame at a time and involves guiding a small transducer over the suspected area of concern to accurately locate a problem. A number of passes of the transducer may be required to confirm a problem and the size and extent of the actual damage. The process is generally reliable but can be cumbersome and time consuming and doesn’t produce a high frame rate video of the scan or conclusive still images of the damage.

Active Thermography: The Fast, Accurate, and Reliable Solution for Detecting Carbon Fibre Frame Defects

Active thermography is the quickest and most reliable method of non-destructive testing and uses a short burst of infra-red heat with a high-speed thermal imaging camera to capture the heat flow in the inspected material without altering it in any way. Enhancement software is then used to produce a heatmap of the item during the excitation and cooling period and can produce a series of x-ray like images for diagnosis. The resulting images clearly show manufactured joints and bonding of the carbon fibre to other component materials such as aluminium dropouts. The severity of any voids, cracks, delamination or defects can then be determined accurately and a full report of the results produced. The report can be used to back warranty or insurance claims with images and professional diagnosis, with recommendations for scrapping or repair.

Discover the Power of Thermography for Carbon Fibre Testing

This sequence of images demonstrates the process of identifying and analysing damage in carbon fibre. Starting with a suspected area, damage may or may not be visible to the naked eye. As infrared exposure begins, the depth and severity of the damage are revealed. The cooling phase further highlights the most compromised areas, offering a comprehensive view to the extent of damage. This thermal imaging process ensures precise detection of hidden issues, providing valuable insights into the integrity of the carbon fibre.

Below are some thermographic images from recent tests

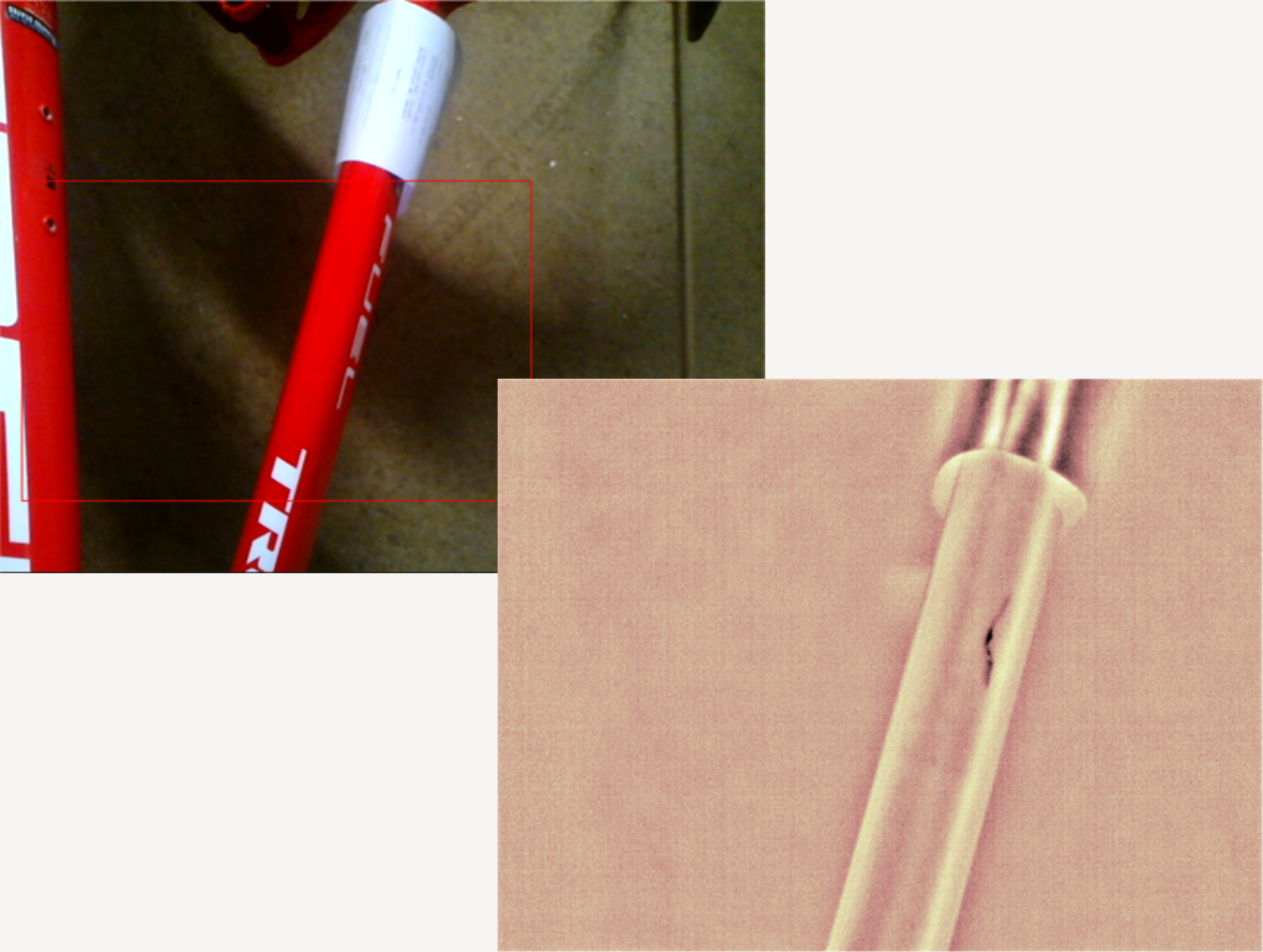

TREK FRAME TOP TUBE SECTION

In the setup photo, a tiny crack in the paintwork was barely visible to the naked eye. Whilst the thermographic image (on the right) shows the full extent of the

damage.

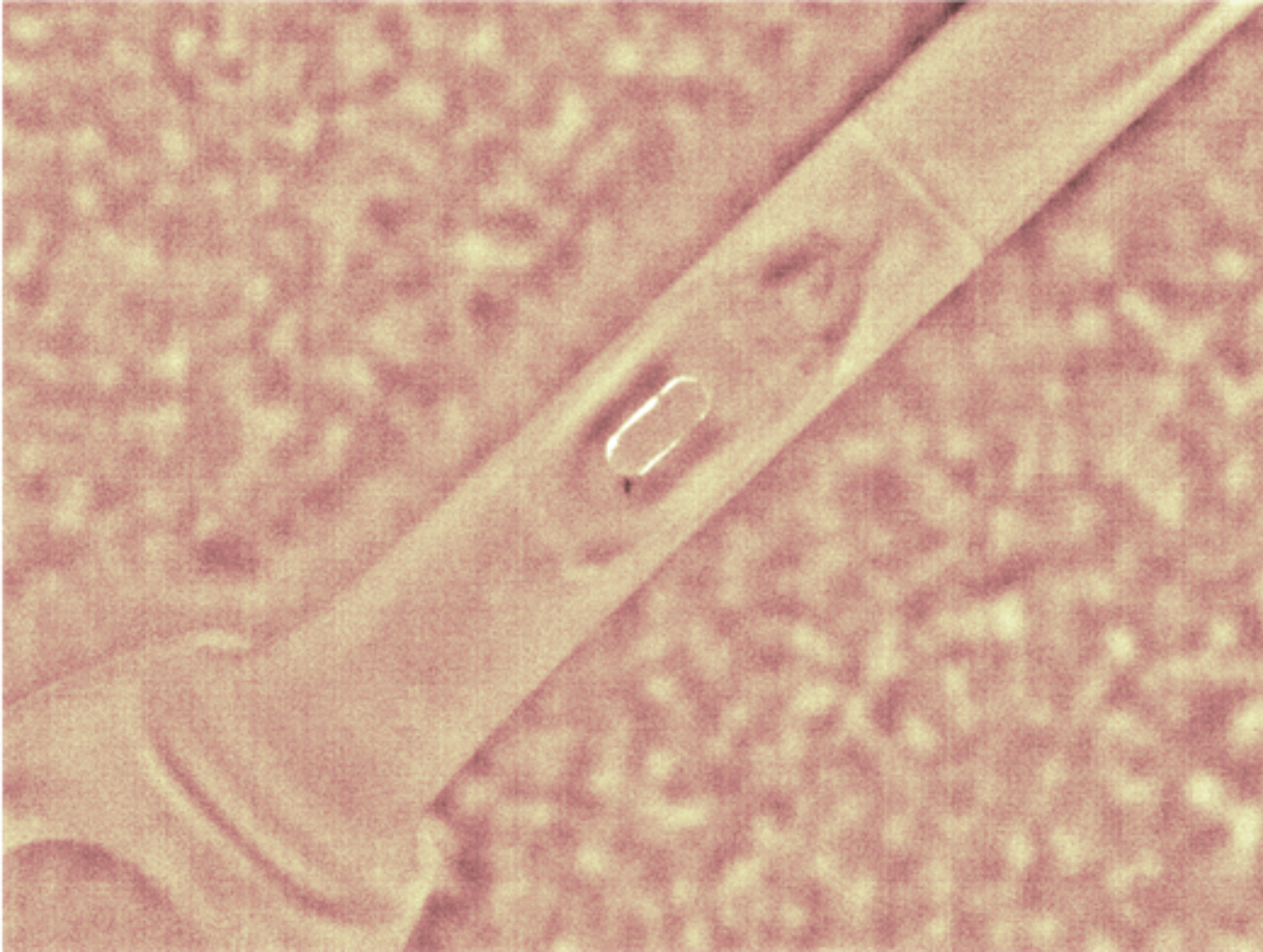

CARBON FIBRE HANDLEBAR

This image shows image of a bonded joint around the area of concern. The outer edge of the joint already shows clear signs that of an external crack. Fibres have broken across the joint and flare white in the image indicating torsional force is the likely reason of failure. Also showing is a hint of the structure and layup in the curve of the drop section.

SPECIALIZED FORK

This is a front view of a fork steerer. It shows delamination of the carbon layers around and above the brake line hole.

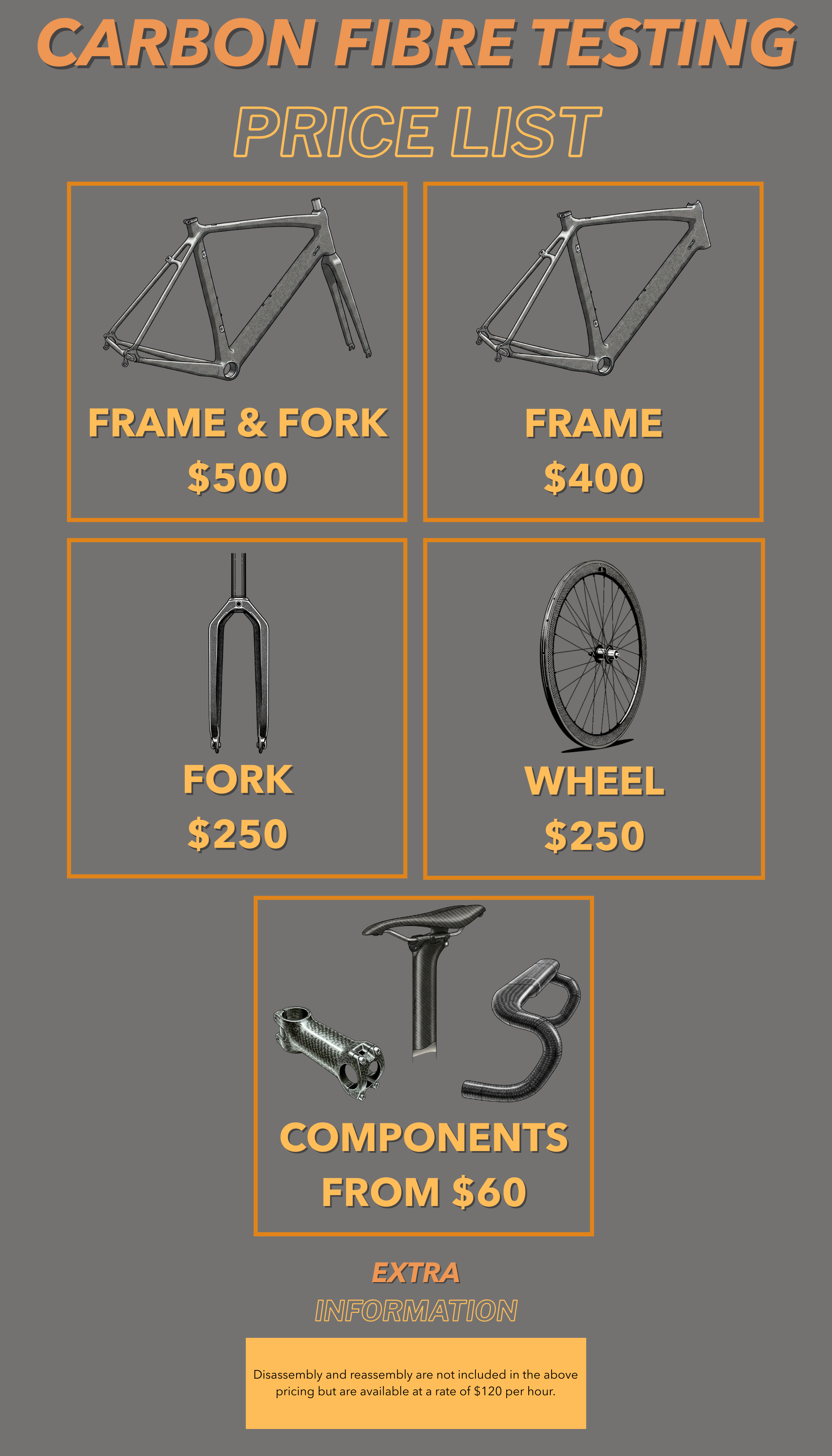

Enquire Now